EXHAUST SYSTEMS

The key to good power is the way an exhaust system is designed. The exhaust system is responsible for allowing a turbocharger to spool up quickly without any unwanted lag while drawing and removing exhaust gasses from an engine in a safe and efficient manner. The standard exhaust system does just this exceptionally well and is whisper quiet. However, there is always room for improvement, with or without the extra noise.

Why should I upgrade my exhaust system?

An exhaust system will always determine the total power output of an engine and how well it responds to other modifications. It also isn’t about how much boost pressure it allows the engine to run at any given time, it’s about how well it lets the engine run the boost pressure that it has. What dyno graphs don’t show is the gains to part throttle and the reduction in turbo lag on the road that a good exhaust system offers. Over the years, I have been developing and testing an exhaust system that allows a turbocharger to spool up as quick as possible and deliver mid-range response and power that punches you in the gut when you put the hammer down.

“An exhaust system will always determine the total power output of an engine and how well it responds to other modifications.”

Anyone can achieve power gains by bolting on a whopping big turbocharger but if you have a poorly designed exhaust system, you are essentially taking a step backwards. A poorly designed exhaust system will affect both boost control and peak power in any case so a larger turbocharger is required in order to compensate for this. Not to mention, the poorly designed exhaust system will cause unwanted turbo lag, meaning an unresponsive and unexciting driving experience. It will also increase back pressure as the engine speed and boost pressure rises. Asking a turbocharger to hold strong boost pressure without letting the excess pressure flow out into the exhaust properly increases the positive pressure before the turbocharger. This reduces scavenging on the exhaust stroke of the combustion cycle. What is “scavenging” you ask? Scavenging is when a cylinder pushes out exhaust gasses while drawing in fresh air at the same time for a clean combustion chamber for the next combustion cycle or “bang”. If this process is not finished completely, the cylinder has a mix of fresh air and exhaust gasses meaning a less efficient bang.

“Anyone can achieve power gains by bolting on a whopping big turbocharger but if you have a poorly designed exhaust system, you are essentially taking a step backwards.”

If all the exhaust gasses are not pushed out of the combustion chamber in time, there is less space for fresh air to enter meaning less potential power. This also results in the engine “detonating” more often which is very dangerous for an engine as compared to an engine running the same boost pressure with a good exhaust system. If positive pressure before the turbocharger is high, modifications to the engine will show their true benefits. To reduce this unwanted positive pressure, a larger turbocharger is needed or ideally, a better designed exhaust system. Fitting a bigger turbocharger will not solve the issue entirely. You must also have a good exhaust system fitted as well.

So what does a good exhaust system do exactly?

The standard headers in your Subaru are a 3-piece unequal length (UEL) type. This is essentially what makes the unmistakable boxer rumble. So if you love the boxer rumble (whoever doesn’t is just mad!), stick with the UEL headers. UEL headers work extremely well if you are running a small to medium sized turbocharger. Porting the standard headers slightly also increases turbo spool up and engine response. That being said though, back-to-back testing against equal length (EL) headers showed that although the UEL headers offered slightly more top end power, the EL headers promoted stronger midrange power without compromising top end power too much. However, you do lose the infamous boxer rumble if you decide to run EL headers.

“It allows a turbocharger to achieve full boost pressure up to 1000rpm earlier. This means more torque and a more responsive and exciting driving experience in both on-boost and off-boost conditions.”

A good exhaust system is one that allows the turbo to spool up as quickly as possible (reducing lag) but does not create large amounts of unwanted turbulence in the process. Turbulence in the exhaust system reduces flow and creates back pressure as the engine speed rises. This unwanted extra back pressure is one of the main causes of a turbocharged engine losing boost pressure quickly as the engine speed rises. The less back pressure there is in an exhaust at higher engine speeds, the better a turbocharger can hold boost pressure more readily and steadily. A good exhaust system that provides the best scavenging effect and offers a greater amount of fresh air to be available in the next bang.

So with all the benefits of a well designed exhaust system, add a combination of more ignition timing and/or more boost pressure and the result: more power! Now let’s break down the exhaust system into seperate components and go into more detail about each one of them.

EXHAUST MANIFOLDS

Commonly referred to as “headers”, this component is a set of runner pipes that connects directly to the engine’s 4x exhaust ports located underneath the engine and routes the exhaust gasses into a common pipe called the “up-pipe” which goes up behind the engine and connects to the bottom of the turbocharger. There are different types of headers available such as unequal length (UEL), equal length (EL), multi-piece type and one piece type.

Should I upgrade the headers? If so, which type would be best?

Compared to a larger turbocharger with a poorly designed exhaust system, a smaller turbocharger mated with a well designed exhaust system will produce the same power with much better engine response. It allows a turbocharger to achieve full boost pressure up to 1000rpm earlier. This means more torque and a more responsive and exciting driving experience in both on-boost and off-boost conditions. To get good low-range power, the turbo needs to boost as fast as it will allow.

So the verdict is, if you are going to run a small to medium sized turbocharger, stick with the UEL headers. A small to medium turbocharger will spool up quickly with a good turbo-back exhaust system so you won’t notice the slight loss of mid-range response when compared to running EL headers. The UEL headers will also promote as much top end power as possible from the small to medium sized turbocharger and you also retain the awesome boxer rumble!

If you are going to run a large sized turbo, EL headers would be recommended to promote quicker spool up for midrange power although you do lose the boxer rumble. The large sized turbocharger with a good turbo-back exhaust system will effectively take care of the slight top end power loss that EL headers tend to have.

DOWN PIPE

The down pipe or “dump pipe” as it is commonly referred to is the part of the exhaust system that bolts onto the back of the turbocharger and joins to the midpipe of the exhaust system located underneath the car. There are different types of down pipes available such as open bellmouth collector, split bellmouth collector and divorced down pipes. The design of this part is very important and determines whether or not the exhaust system is well designed or poorly designed.

Which type of down pipe is the best one to use?

I have tested every type of down pipe and found that by using an split bellmouth collector down pipe, it produced the best results in producing the most extra power at lower engine speeds. The diameter and length of the taper on the open mouth collector also plays a role in how much torque an engine produces and what engine speed it delivers it at. Larger collectors allow the hot exhaust gasses to expand and flow properly. If the hot gasses cannot expand, then the flow slows down. However, as the hot gasses cool down, the size of the collector needs to reduce accordingly in order to keep the flow going otherwise a loss of torque will result.

Is there any benefit of having a splitter in the collector?

Yes, definitely. This is because all of the excess flow coming from the wastegate is flowing directly into the path of the main flow coming from the exhaust turbine. The wastegate can only open to a maximum of ~30 degrees so the interruption of the two flow paths reduces gas flow, creates unwanted turbulence and increases pressure in the headers. This unwanted pressure in the headers can be reduced by adding a splitter in the collector to seperate the wastegate flow and exhaust turbine flow from the turbocharger. With a splitter fitted, it’s now effectively a split bellmouth collector.

The position and length of the splitter in the collector is extremely important in order for it to work properly. If the wastegate flow is seperated from the exhaust turbine flow for too long, it reduces the amount of room left inside the collector for the main flow to expand in order to flow. So it’s important that the splitter be as short as possible once it is inside the collector but also needs to fit in the back of the turbo neatly providing a proper seal between the splitter and the turbocharger’s exhaust housing. TD type and VF type turbochargers use different length splitters so it is important that the correct one is used to suit your turbocharger.

DIFF-BACK

As the name states, this refers to the section of the exhaust system that starts from underneath the rear diff subframe and goes into the muffler. This section is usually connected to the midpipe located underneath the car by using a flange with a couple of nuts and bolts. If you only change the diff-back section and leave the rest of the exhaust system unchanged, this only changes the sound of your exaust system with no performance gains whatsoever mainly because of the type of muffler. However, if you have a complete exhaust system that is well designed, changing the design and size of the diff-back pipe actually does have an effect on the way your engine produces torque as I shall now explain.

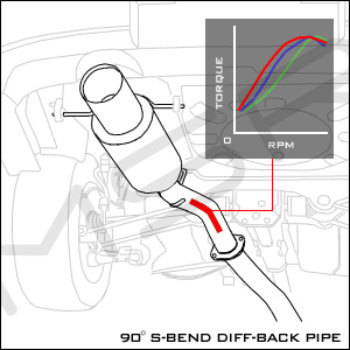

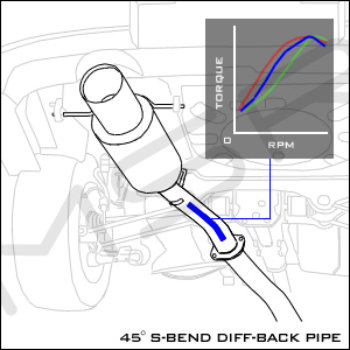

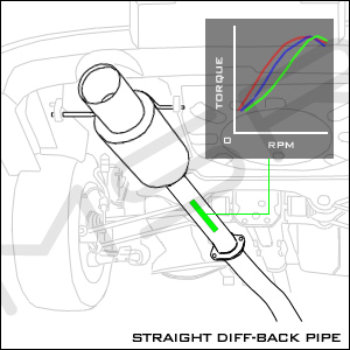

After carrying out extensive testing, I found that the design of this pipe had a huge effect on an engine’s torque curve. By using an “S” bend leading into the rear muffler with 2x 90 degree mandrel bent pipes back to back, this produced the most torque in midrange engine speeds. Reducing the angle from 90 degrees to 45 degrees moved peak torque to higher engine speeds with a slight loss in midrange torque. An almost straight pipe going straight into a muffler produced a very linear powerband with a smooth delivery of power due no “kick” as a result of the noticable loss of torque in midrange engine speeds. After speaking with Prodrive themselves, they also confirmed this to be the case.

Changing the diameter of the diff-back pipe that leads into the muffler from 3″ to 2.5″ also helps improve midrange torque for Subaru engines that do not have AVCS (or variable valve timing). Pressure at the turbo is not affected by this decrease in diameter. As a matter of fact, it actually helps to keep exhaust gasses flowing for better power.

Find us

- © Michael South Engineering (MSR)

- - Oz Website Design